Spare parts for Interpump: powering the world’s high-pressure systems

Wherever water needs to be controlled with incredible force — in agriculture, industrial cleaning, mining, food processing or car-wash systems — the signature roar of an Interpump high-pressure pump can often be heard. As the world’s largest manufacturer of professional high-pressure plunger pumps, the Italian Interpump Group has spent decades engineering machines that deliver precision, durability and performance even under the harshest conditions.

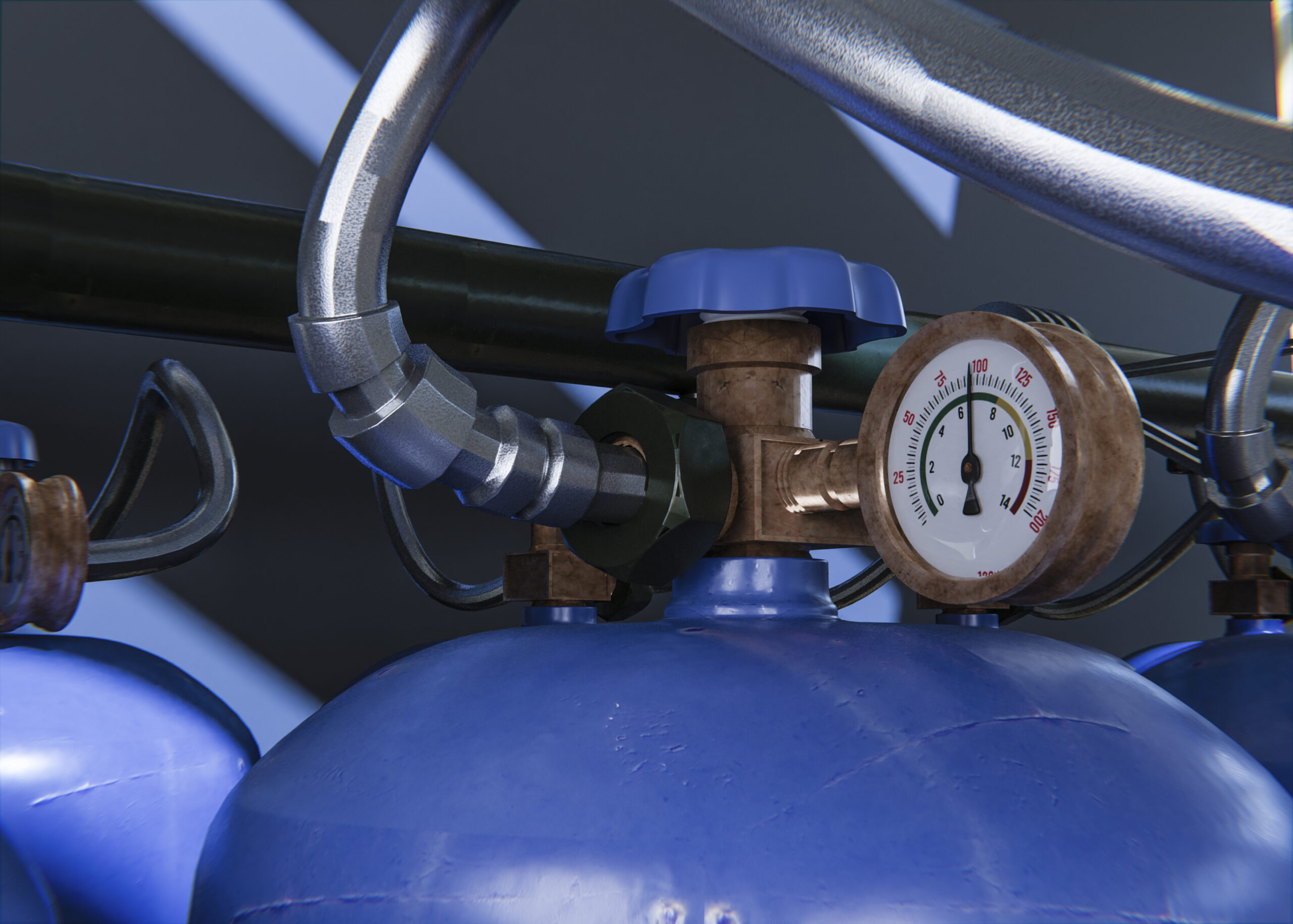

From stainless-steel pump heads to ceramic plungers and advanced sealing systems, Interpump technology is designed to take water and transform it into a powerful industrial tool. And behind every reliable pump is one essential foundation: premium spare parts for Interpump units that keep them pushing water at extreme pressures day after day.

Spare supplier for Interpump: keeping pressure high and downtime low

Interpump pumps operate in environments that are unforgiving. They power heavy-duty cleaning machines, pressure washers, fire-fighting units, industrial sanitation equipment, oil and gas installations, and countless other applications where failure is simply not an option.

In these fields, the smallest component — a worn valve, a cracked seal, a degraded plunger — can reduce pressure output or shut down the entire system. That is why choosing a reliable spare supplier for Interpump pumps is essential. The right supplier ensures that every pump maintains optimal pressure, efficiency and operating life, even during continuous or high-cycle workloads.

The Interpump legacy: Italian engineering built for extreme performance

Founded in the 1970s, Interpump revolutionized the high-pressure pump industry by introducing pumps with ceramic plungers and stainless-steel construction, dramatically increasing lifespan and efficiency. Over the decades, the company has expanded into a global group producing:

- High-pressure plunger pumps: the heart of industrial cleaning and professional pressure-washing systems.

- Hydraulic components: motors, cylinders, valves and power-take-off systems used in heavy industry.

- Pump accessories: safety valves, manifolds, nozzles, injectors and regulators.

- Food and beverage components: stainless steel processing equipment through the group’s expanded divisions.

The company’s pumps are known for their balance of power and reliability — dense mechanical assemblies built to operate continuously at pressures from 100 to more than 500 bar. To keep these machines operating at their peak, technicians rely on well-matched Interpump spare parts designed specifically for each model.

Spare parts for Interpump pumps: precision under pressure

High-pressure water pumps are intricate machines. Each stroke of the plunger, each movement of a valve, and every micron of seal compression affects performance. Using high-quality spare parts for Interpump ensures correct flow rates, stable pressure and long service life.

Commonly required Interpump spare parts include:

- Ceramic plungers: resistant to wear, heat and chemical corrosion.

- Seals and O-rings: high-pressure sealing specialists tailored for water, detergents or industrial fluids.

- Valve kits: suction and delivery valves that regulate flow and maintain stable pressure.

- Manifolds: high-strength stainless-steel or brass pump heads.

- Pump bearings: components that absorb axial and radial load in continuous-duty applications.

- Gaskets and packings: essential for leak-free operation.

- Connecting rods & crankshafts: mechanical components for restoring full pump performance.

Replacing these parts with precision-engineered equivalents preserves the pump’s original factory performance, reducing energy consumption and lowering long-term operational costs.

Supplier for Interpump users: expertise that matters

A true supplier for Interpump technology must understand how these pumps behave under pressure. They need to identify wear patterns, match part codes correctly, and provide critical components quickly — especially to industries where downtime has direct financial impact.

A professional supplier offers:

- Exact part identification: ensuring compatibility with specific Interpump pump series and revisions.

- High-quality spare parts: built to endure extreme pressures and continuous operation.

- Fast international delivery: often essential for cleaning contractors, carwash operators, food factories and energy sites.

- Technical guidance: support on installation, assembly torque, lubrication and maintenance intervals.

- Preventive-maintenance planning: helping companies avoid costly breakdowns.

When a pump is the heart of a machine, a good supplier becomes the heartbeat of reliability.

The pressure of performance: why Interpump spare parts matter

Whether a pump is blasting grime off industrial machinery, sanitizing food-processing floors, feeding cleaning robots, or powering agricultural systems, Interpump units are expected to perform with unwavering strength. Their rugged construction makes them a favorite among professionals who need reliability year-round.

However, even the toughest engineering requires the right maintenance. With consistent inspection and the use of genuine or high-quality Interpump spare parts, these pumps can run for thousands of hours with minimal wear and consistent output.

Spare supplier for Interpump: strength, reliability and confidence

Working with a trusted spare supplier for Interpump systems ensures that your high-pressure equipment remains dependable and efficient. In industries where pressure is everything, the right spare parts protect performance, extend pump life and keep operations moving without interruption.

Interpump pumps are built to endure — and with the right parts, they will continue delivering powerful results, day after day, year after year.

Get in touch with us