Spare parts for Frictec: precision wear parts that keep lines moving

In the high-speed world of packaging and industrial processing, many unseen components exert enormous pressure each second. One of the specialists behind these critical parts is Frictec Ltd, a UK-based manufacturer of precision knives and wear parts for packaging machines and industrial applications. With decades of experience and a global footprint, Frictec plays a behind-the-scenes but vital role in maintaining efficiency, uptime and quality.

These machines may not always be front of stage, but they are the bedrock of global consumer-goods manufacturing. From flow-wrap systems and aseptic packaging lines to extrusion cutters and bagging stations, the correct parts make the difference between smooth production and costly downtime.

Spare supplier for Frictec systems: why specialist parts matter

When your production line runs at hundreds or thousands of cycles per minute, even a single part misaligned or worn out can halt output or degrade quality. That is why identifying a dedicated spare supplier for Frictec systems is so important. The right spare parts preserve cutting accuracy, minimize stoppages and support high-volume operations across industries.

Frictec’s domain: specialist knives and wear parts for packaging and processing

Frictec specialises in manufacturing high-quality packaging machine knives and wear parts, serving a broad range of sectors including food packaging, beverages & liquid, closures/caps, frozen food, pharmaceuticals and personal care. :contentReference[oaicite:1]{index=1}

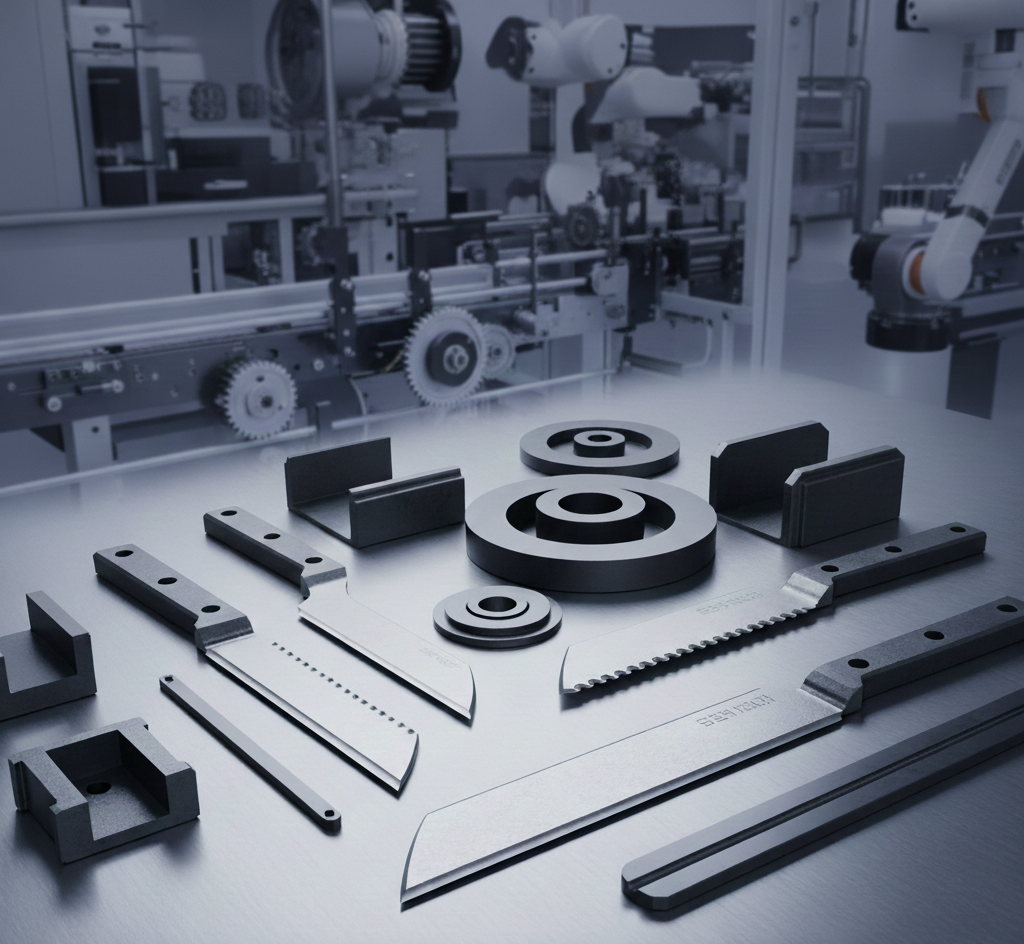

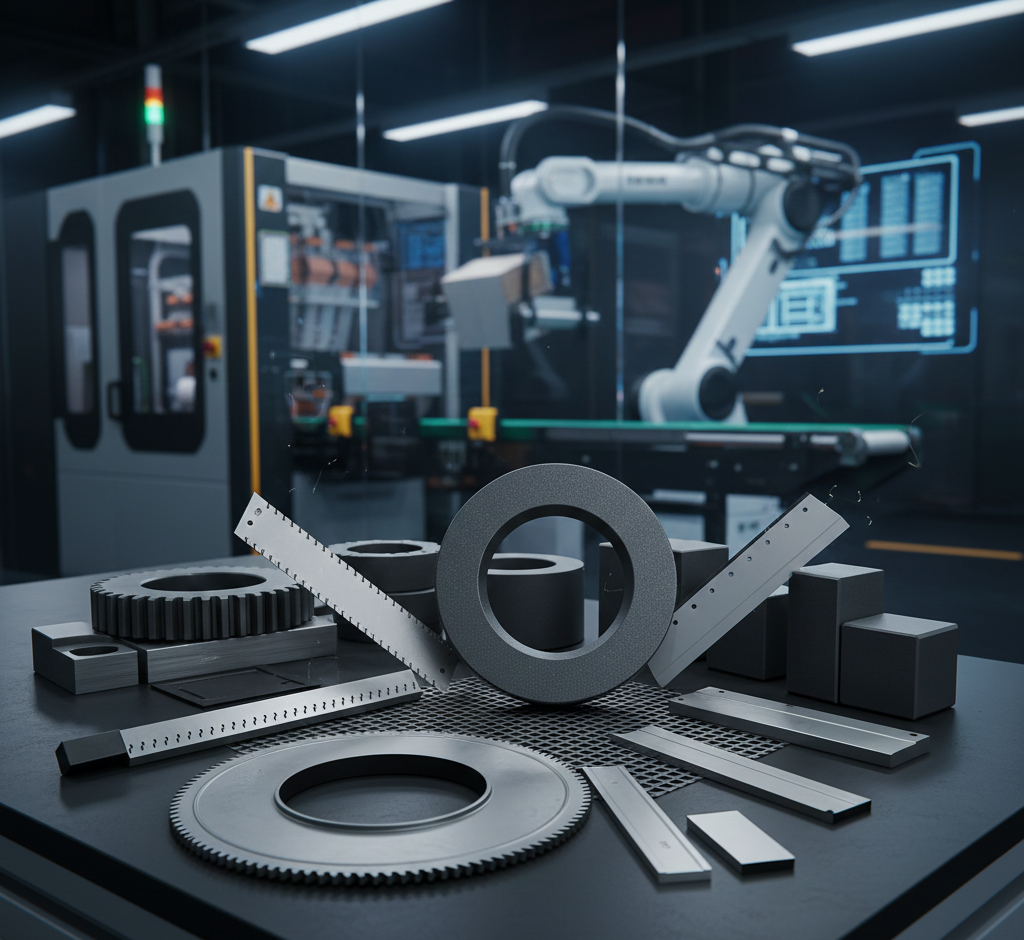

Some highlights of what they deliver:

- Circular and shear knives used in flow-wrap, extrusion and guillotine systems.

- Sachet, tube and window-knife systems for highspeed aseptic packaging and multiformat lines.

- Wear components made of aluminium, steel, plastic and coated materials—customised to high demand applications.

- A proprietary material called **TMC45**, developed in-house, for extended knife life in demanding applications.

Frictec’s focus on wear parts means that production lines stay sharper, faster, cleaner and more reliable—leading to lower downtime and better output.

Spare parts for Frictec machines & systems: tiny parts, huge impact

While one might think of “knives” as simple, the reality is far more complex. Cutting edges must maintain exact tolerances, minimal burrs, perfect angles and consistent hardness. For high-speed packaging, minor variation can lead to jagged cuts, material waste, rejected product or machine damage.

Using correct spare parts for Frictec equipment—whether blades, blocks, wear plates, inserts or bearings—ensures production keeps going at full speed, without compromise. Many parts are reverse-engineered by Frictec to match OEM references and functional demands.

Common components include:

- Shear knives & choppers for extrusion and guillotine systems.

- Circular knives for bagging, sachet and wrap applications.

- Wear plates / anvil blocks for flow-wrap and over-wrap machines.

- Sachet/tube window knives for liquid-food and pharmaceutical packaging.

- Custom wear parts in aluminium, steel, plastic or coated substrates for specific machine zones.

Supplier for Frictec users: what true support looks like

A professional supplier for Frictec components does more than maintain a parts list. They offer: accurate identification of part numbers and material grades, rapid delivery to global operations, reverse-engineering for obsolete items, and advisory support on wear patterns and replacement intervals.

Frictec itself emphasises that they work in partnership with major global companies, delivering bespoke solutions that reduce downtime and annual cost.

Why this matters: reliability, precision & cost control

In packaging and processing plants, inefficiency or stoppage mean real money—wasted material, lost production, delayed shipments. When knives dull, shear quality suffers; when wear plates erode, machine tolerance is lost; when components are out of spec, throughput drops.

By partnering with a trusted spare supplier and keeping genuine spare parts for Frictec systems in stock, production teams gain stability, predictable costs and improved maintenance cycles. The long life of parts like TMC45-based knives also means fewer change-overs and less unplanned maintenance.

Spare supplier for Frictec: your ally in continuous production

Whether you run aseptic cartons, high-speed wrap machines, extrusion cutters or tube-filling lines, the unseen components matter. With the right spare supplier for Frictec equipment, you ensure your line keeps moving smoothly, your product stays flawless, and your team stays ahead of potential breakdowns.

Frictec design, manufacture and support the wear parts. Your supplier keeps them in stock, correctly identified, and ready for action. That’s how uptime becomes the rule, not the exception.

Get in touch with us